BWF AirslideTec - High quality air slide fabric.

Optimal solution for dry powder transportation.

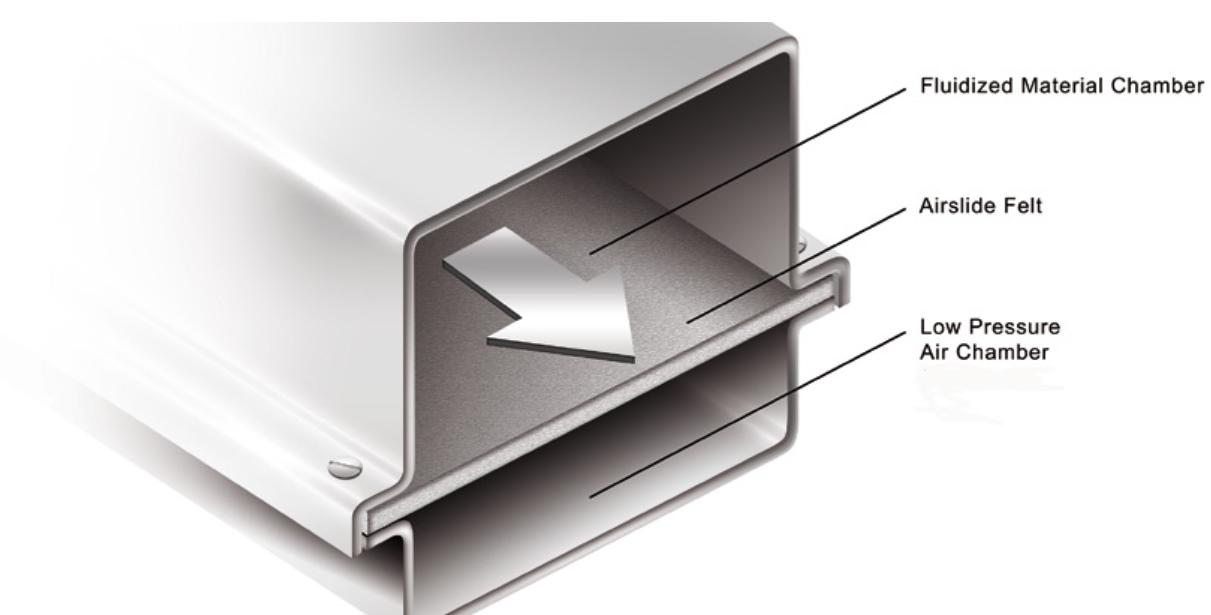

BWF AirslideTec's quality needle felt is the ideal solution for: dry powder transport - in the cement industry, gypsum production, transport of aluminum powder, fly ash handling in coal-fired power plants and for transporting bulk powdered goods.

Crafted with a smooth and uniform pore structure, the BWF AirslideTec quality Air slide fabric is designed to deliver consistent airflow throughout the product's operating life. BWF AirslideTec felts ensure lower operating costs, less downtime and a more efficient installation process.

Advantages of BWF AirslideTec Air slide fabric:

Analysis of the outstanding advantages of BWF AirslideTec Air slide Fabric more details.

Application of BWF AirslideTec Air slide fabric for Silo bottom lining more details.

Frequently asked questions when using Air slide fabric more details.

Some typical fabric codes BWF AirslideTec:

|

SPECIFICATIONS |

BWF AirslideTec |

BWF AirslideTec |

BWF AirslideTec |

BWF AirslideTec |

|

|

TAN 7785 |

TAN 9381 |

TAN 9253 |

TAN 9428 |

|

Material composition |

polyester |

A site: para-aramid |

polyester |

polyester |

|

Weight [g/m 2 ] |

3200 |

3000 |

2500 |

2500 |

|

Thickness [mm] |

7-8 |

8.5 |

5-6 |

5-6 |

|

Density [g/ cm3 ] |

0.45 |

0.35 |

0.45 |

0.45 |

|

Air permeability |

9 |

21 |

4 |

1.7 |

|

Air permeability |

150 |

70 |

330 |

800 |

|

Tension |

||||

|

Vertical [daN] |

400 |

500 |

> 300 |

> 300 |

|

Horizontal [daN] |

600 |

950 |

> 600 |

> 600 |

|

Elongation at break |

||||

|

Vertical [%] |

30 |

25 |

25 |

25 |

|

Horizontal [%] |

40 |

26 |

30 |

30 |

|

Temperature endurance |

||||

|

Continuous [°C] |

150 |

200 |

150 |

150 |

|

Peak [°C] |

200 |

A site: up to 500 |

200 |

200 |

|

Processing method |

heat-set/ calendered |

heat-set/ calendered |

heat-set/ calendered |

heat-set/ calendered |