Airslide Fabric - Frequently Asked Questions

1. Overview of the BWF AirslideTec Product

BWF Protec has been developing and manufacturing BWF AirslideTec material for over 20 years.

We supply AirslideTec fabric to many industrial plants around the world.

BWF AirslideTec is used in the transportation of powders, hot ash, or other bulk materials. The product details here.

2. How does the influence of blowing air pressure affect the operating process of the air slide fabric? What indicators should the fan power be adjusted based on, and what values are necessary to ensure proper operation?

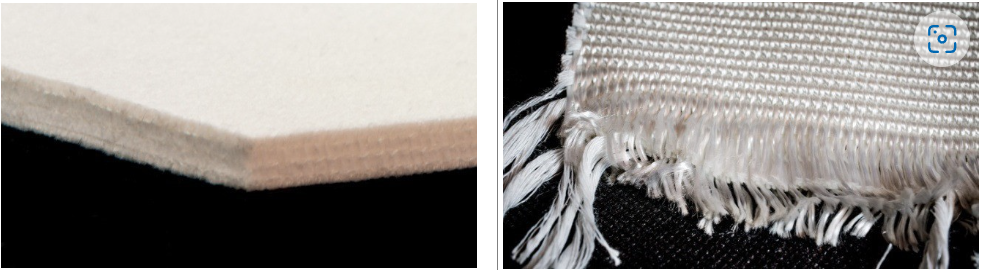

BWF AirslideTec material is a needle-felted fabric with a high density. Due to the manufacturing method (needle punching), the felt has millions of very small, microscopic holes. Conventional woven air slide fabric does not have this advantage because its holes are larger, coarser, and irregular.

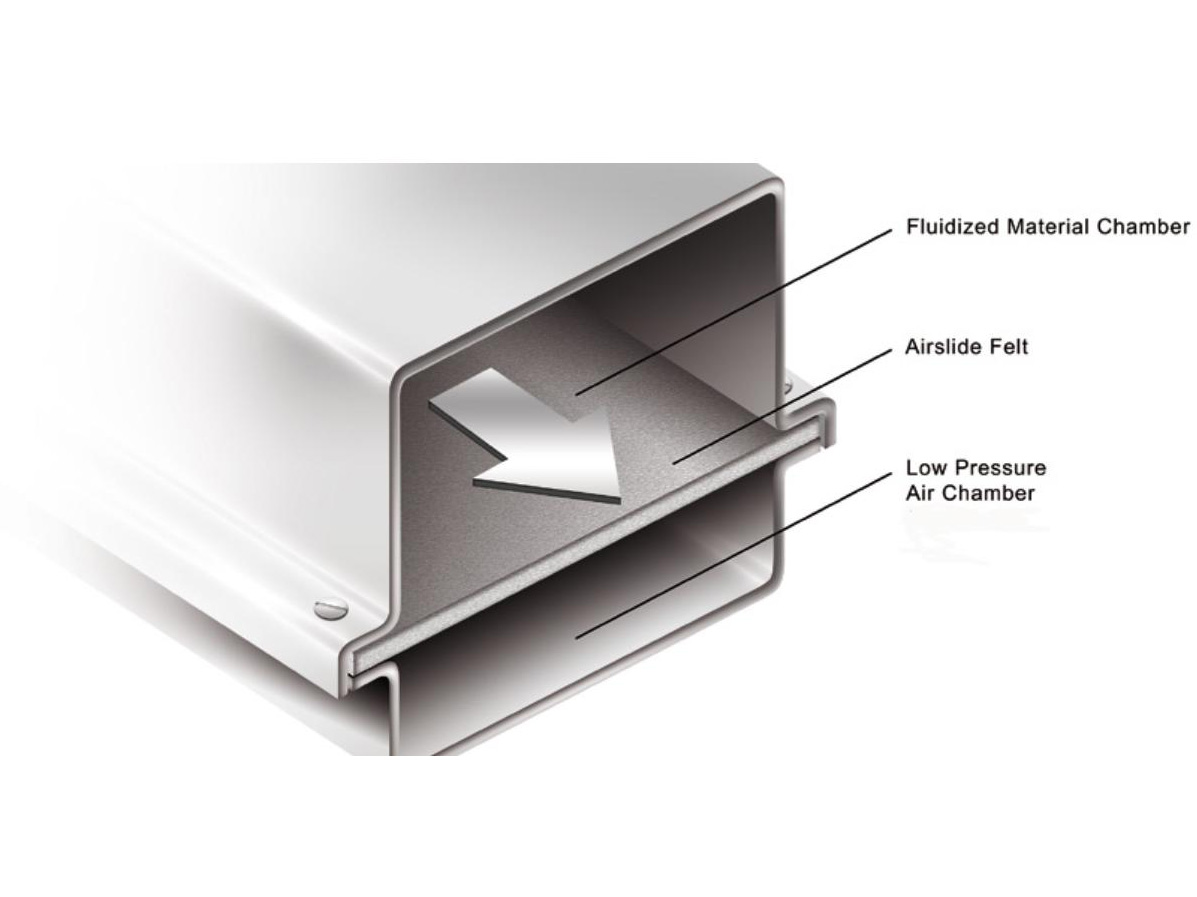

Through these tiny holes, pressurized air can pass through and create a very stable and uniform air cushion between the BWF felt and the bulk material, allowing for smooth flow of the bulk material.

Of course, we need to adjust the air pressure to be suitable for the production process. The pressure adjustment (fan power adjustment) is based on observing and evaluating the air cushion on the surface of the air slide fabric: a moderate cushion (neither too weak nor too strong) will create a stable and efficient flow.

This process is very easy to implement with BWF AirslideTec due to the uniform and stable properties of the material, which is very difficult to achieve with conventional woven fabrics.

3. Advantages of BWF AirslideTec fabric in the installation process.?

BWF AirslideTec material is a combination of reinforced fabric layers in the middle with countless needle-punched fibers. Therefore, it has very stable dimensions, high durability, and low elongation.

As a result, the installation process will be easier and more material-efficient compared to conventional woven fabrics. Woven fabrics must be pulled very tight during installation both horizontally and vertically. If not, the air slide fabric will sag during use.

BWF AirslideTec material is also installed under tension but does not require as much tension as woven fabric. The tension is just enough for the air slide fabric to achieve flatness upon installation.

Creating bolt holes on the felt is very easy and can be done with a hot rod. Cutting the felt fabric is also straightforward. The holes or cut edges will not fray and do not need flame treatment after cutting.

In contrast, woven fabric is more challenging to cut and create holes. The edges and holes tend to fray at the cut edges and need to be treated with fire to address this issue.

In conclusion, the construction of AirslideTec fabric is faster, easier, and more cost-effective compared to conventional woven air slide fabric.

4. How do debris such as bolts and steel falling onto the chute fabric affect the lifespan of the airslide? At the discharge point, heavy objects often fall and impact the chute fabric. Provide solutions to minimize wear at the discharge point.

It is clear that when debris, bolts, nuts, steel, etc., fall onto the air slide, it is not good! The first impact is that the flow of material becomes unstable or may even stop. Furthermore, such "foreign objects" can reduce the lifespan of the air slide. The first solution is to minimize the entry of these foreign objects into the air slide (but unfortunately, we cannot advise you on how to prevent it). The second solution is to use a "perforated steel plate" at this position. The third solution is to use the "High Abrasion Resistant (HAR) Airslide from BWF" at this location.

5. What are the dimensions of the fabric, and is it easy to install and cut to size? Can the company pre-cut it according to the required dimensions?

The maximum fabric width of BWF AirslideTec is 2150 x 32,000 mm. And Yes, we can cut the fabric to the dimensions requested by the customer.

6. Due to the extremely hot and humid climate in Vietnam, especially during the rainy season, high humidity causes cement to easily stick in the air slide, and if the cement is not fully dehydrated, can the air flow still pass through? With temperatures reaching up to 60 degrees Celsius, what is the maximum allowable humidity for operation??

If the cement has a higher humidity level and shows signs of sticking, the air pressure must be adjusted to a higher level. At this point, air can still pass through the fabric, and material transport occurs due to the micro-perforated structure of the felt. The air cushion that separates the cement powder from the chute fabric prevents moisture from the cement powder from penetrating the fabric, as the air is blown from underneath the fabric upward.

Regarding the issue of "maximum allowable humidity at 60°C," we do not have a precise answer. BWF AirslideTec materials are used in many cement plants across various countries (India, Thailand, the Philippines, etc.), and we have not encountered any issues related to humidity parameters.

7. What is the size of dust particles that can pass through the fabric?

As mentioned, the felt material has a micro-perforated structure. This structure acts like a "solid and tight barrier," preventing any dust particles from passing through to the underside.

8. What is the chemical resistance and temperature tolerance of the material?

The BWF AirslideTec fabric is typically made from polyester, which can operate at temperatures up to 150°C and has good acid and oxidation resistance, but is limited in terms of hydrolysis and alkalinity.

Once you know the exact operating environment of your system, please contact us to help you select the most suitable fabric material. For example, for high-temperature applications (such as hot ash), we offer Kevlar (para-Aramid) material that is suitable for high temperatures and has higher chemical resistance.

9. What is the load-bearing capacity of the air slide fabric at the bottom of the silo, where there is a significant weight?

The BWF AirslideTec fabric is also used in silos (in the cement industry). So far, we have not received any negative feedback or comments about AirslideTec not performing well in this position.

However, we do not have a precise answer regarding the parameters for this question, as each silo has different diameters, heights, and load capacities.

Contact us to experience the difference and advancement by the most mordern Airslide felt technology ASAP:

LUONG GIA TECHNICAL AND TRADING INVESTMENT JOINT STOCK COMPANY

Add: No. L7-18 Dai Kim Urban Area, Daikim ward, HoangMai District, Hanoi City, Vietnam.

Phone: 0983.838.332/ Email: luong.quang.trung@lgtech.com.vn

Website: www.lgtech.com.vn