Outstanding advantages of BWF AirslideTec compared to other woven style air slide on the market

BWF AirslideTec - Needle Felt Air Slide Fabric for Dry Powder Transportation.

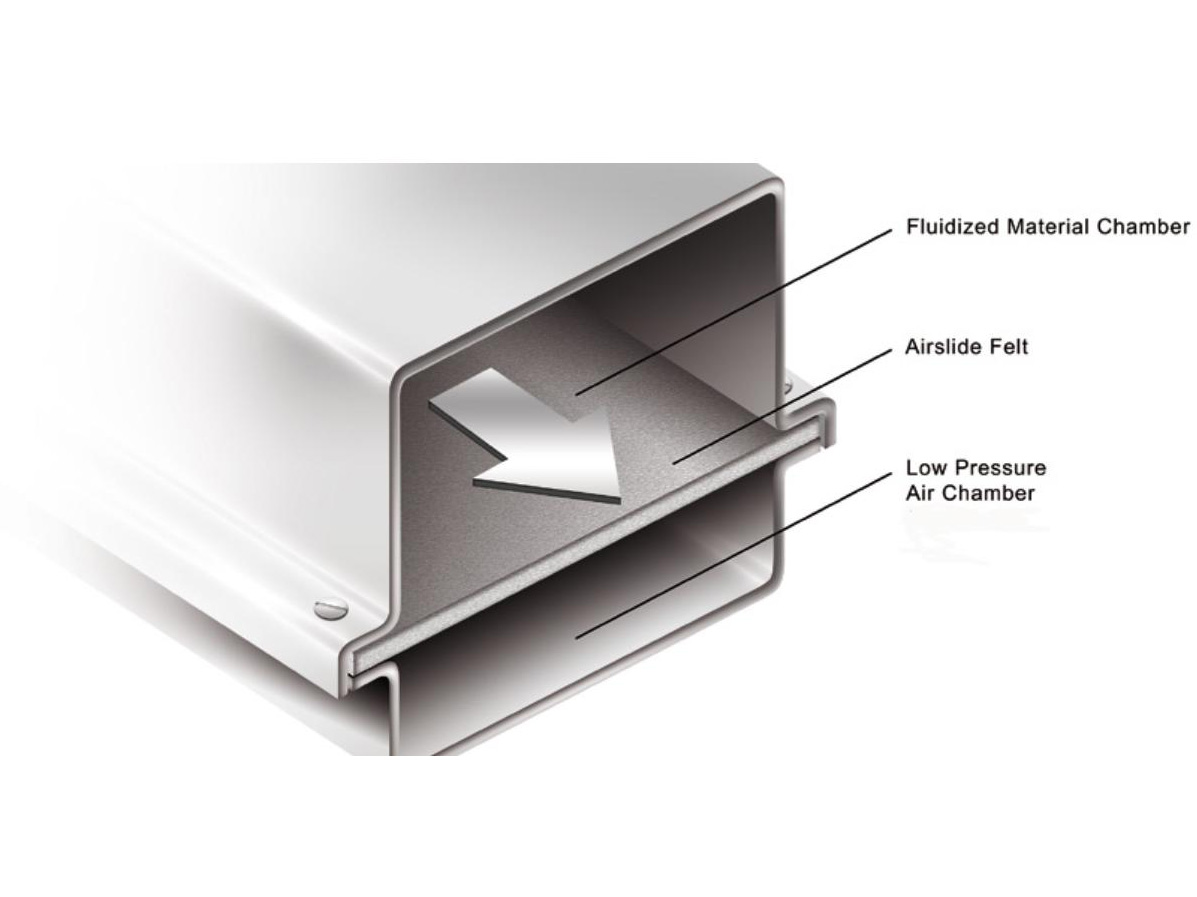

BWF AirslideTec needle felt air slide is the ideal solution for transporting dry bulk materials. It is manufactured with a fine, uniform pore structure and is designed to provide a consistent airflow throughout the entire operation of the product.

Main product applications include:

- Cement industry: Processing raw materials, processing cement after crushing/milling

- Coal thermal power plant: Floating ash treatment

- Aluminum: Powder processing

- Transporting powder in large quantities

Benefits:

- The operating life is greater than that of the woven type

Deflection is minimum - Resistant to rotton and mold

- Reduce emission

- Avoid worn and torn

Compare BWF AirslideTec - Needle felt Airslide with conventional woven Airslide

|

|

BWF AirslideTec |

Woven airslide |

|

Tear resistance |

Does not fray after cutting or making holes. No heat welding required in the cutting surface. Does not fray even if the surface is damaged during operation. |

Due to the woven structure, the fibers will fray at the edges or at the holes after cutting. Heat sealing the edges is necessary. If a thread is damaged, the fabric will fray and unravel. |

|

|

|

|

|

|

⇒ Very Easy to replace from woven fabric to BWF AirslideTec |

|

|

|

BWF AirslideTec |

Woven airslide |

|

Anti-stretch |

Needle felt airslide doesn’t need to stretch to installation |

Has to stretch about 2% before installing and keep stretching while operating. |

|

|

⇒ BWF AirslideTec easy to install, maintenance and durable than the woven one |

|

|

|

BWF AirslideTec |

Woven airslide |

|

Air pore |

Thousands of very small and uniform fabric holes per square centimetre and a very flat rolled surface provide uniform airflow and do not allow dust and powder particles to penetrate |

The coarse weave structure cause from thick fibers has large fabric pores that allow dust and powder particles to penetrate the fabric and block airflow |

|

|

|

|

|

|

⇒ BWF AirslideTec has anti-dust surface, very well and even air flow compare to woven air slide |

|

|

|

BWF AirslideTec |

Woven type |

|

Air leaking |

The flat and uniform structure of needle felt type fabric provides better sealing ability. The smooth surface allows for a better seal, ensuring no air leakage |

The rough, irregular surface of the textile makes it difficult to seal the system, specially the edge of the cutting position |

|

|

|

|

Conclusion: Needle felt BWF AirslideTec – Needle felts air slide has many outstanding advantages compared to the common woven air slide fabric on the market. BWF AirslideTec has a solid structure, small, uniform fabric holes, well-performing air circulation, and outstanding durability. BWF AirslideTec helps increase material transportation efficiency, while also reducing incidents, reducing machine downtime for maintenance and fabric chute replacement, which is a very important factor in the production process.

Instructions for fabric cutting and installation

For cutting process BWF AirslideTec fabric, we encourage you to carefully review the following instructions:

- Mark the felt and cut with a cutter or sharp knife

- After perforate (not using a hot iron tip) or cutting, seal the edge with a hot soldering iron or with a flame. The polyester will turn light brown - take care not to burn the fibers.

For assemble process: You should seal all flange connections that contact with the fabric by a silicone mixture.

Stretching the fabric while installing is unnecessary.

Contact us to experience the difference and advancement by the most mordern Airslide felt technology ASAP:

LUONG GIA TECHNICAL AND TRADING INVESTMENT JOINT STOCK COMPANY

Add: No. L7-18 Dai Kim Urban Area, Daikim ward, HoangMai District, Hanoi City, Vietnam.

Phone: 0983.838.332/ Email: luong.quang.trung@lgtech.com.vn

Website: www.lgtech.com.vn